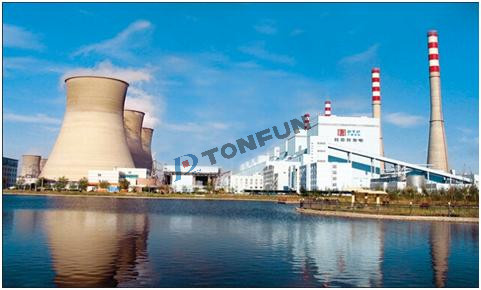

The latest unit in the world largest thermal power plant bided by TONFUN was operated successfully for 168 hours

发布时间:2017-02-27 10:39:26

The no.10 unit of the fifth phase project of Inner Mongolia Datang international Toktor power generation co., ltd. passed 168 hours of trial operation on the afternoon of February 25, China news service reported. At this point, the companies five phase expansion project two domestic 660,000 kw ultra-supercritical units are put into commercial operation, the total installed capacity of 6.72 million kw, become the world's largest thermal power plant in service. After the completion of the units, Toktor power Generation Company will play a more important role in environmental protection, ensuring China's energy security and promoting western development and other fields.

Toktor co., a state-owned enterprise, has taken the lead in implementing various national and local environmental protection policies and completed the denitrification and operation of 10 units before July 2014, which can reduce nitrogen oxide emissions by 40,200 tons annually, CNR reported Thursday. Not only that, and invest 600 million yuan to ultra-low emissions of 10 units, has now been completed 1, 3, 4, 5, 6, 8, 6 units of ultra-low, unit 2, 7, 11, 12, 2017 completed renovation, five phase of the 9, 10 units production of ultra low emission is achieved, the unit discharge is close to the gas emission value of the unit.

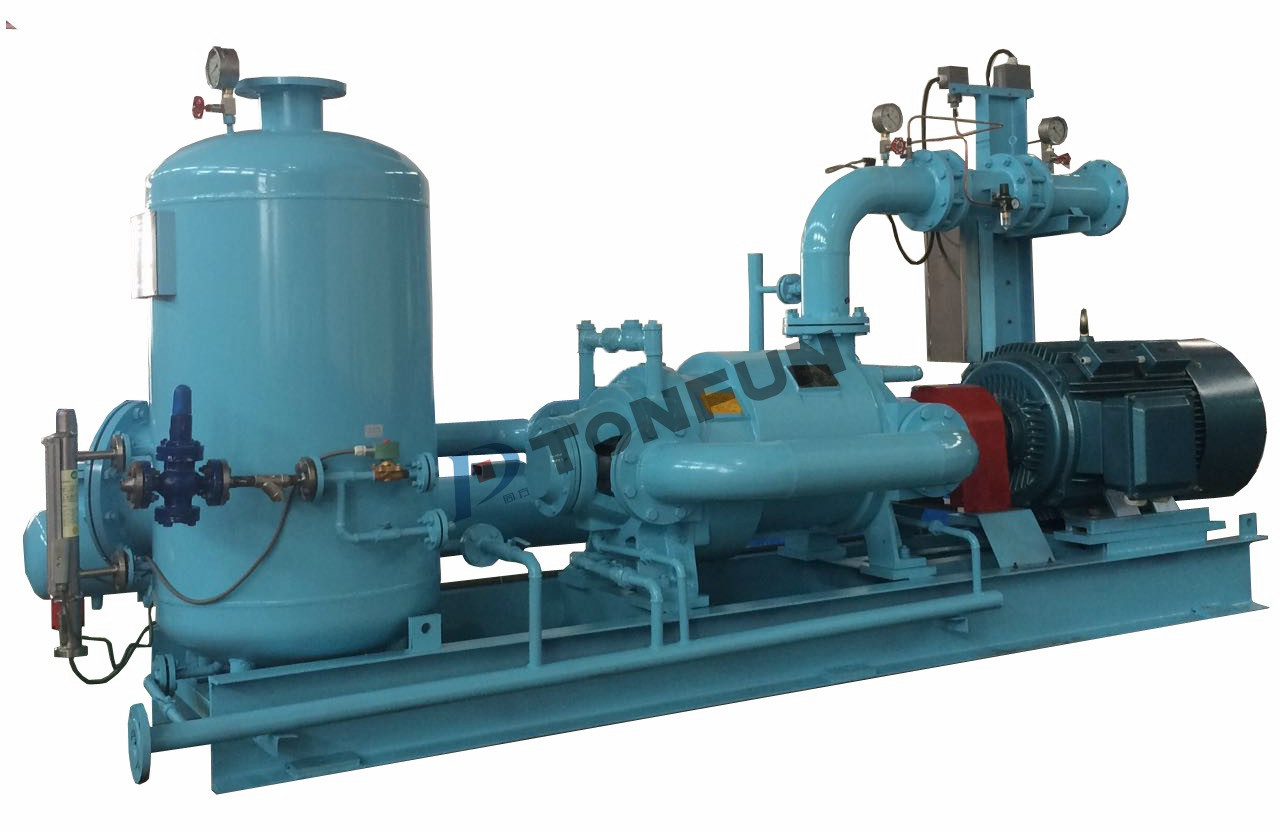

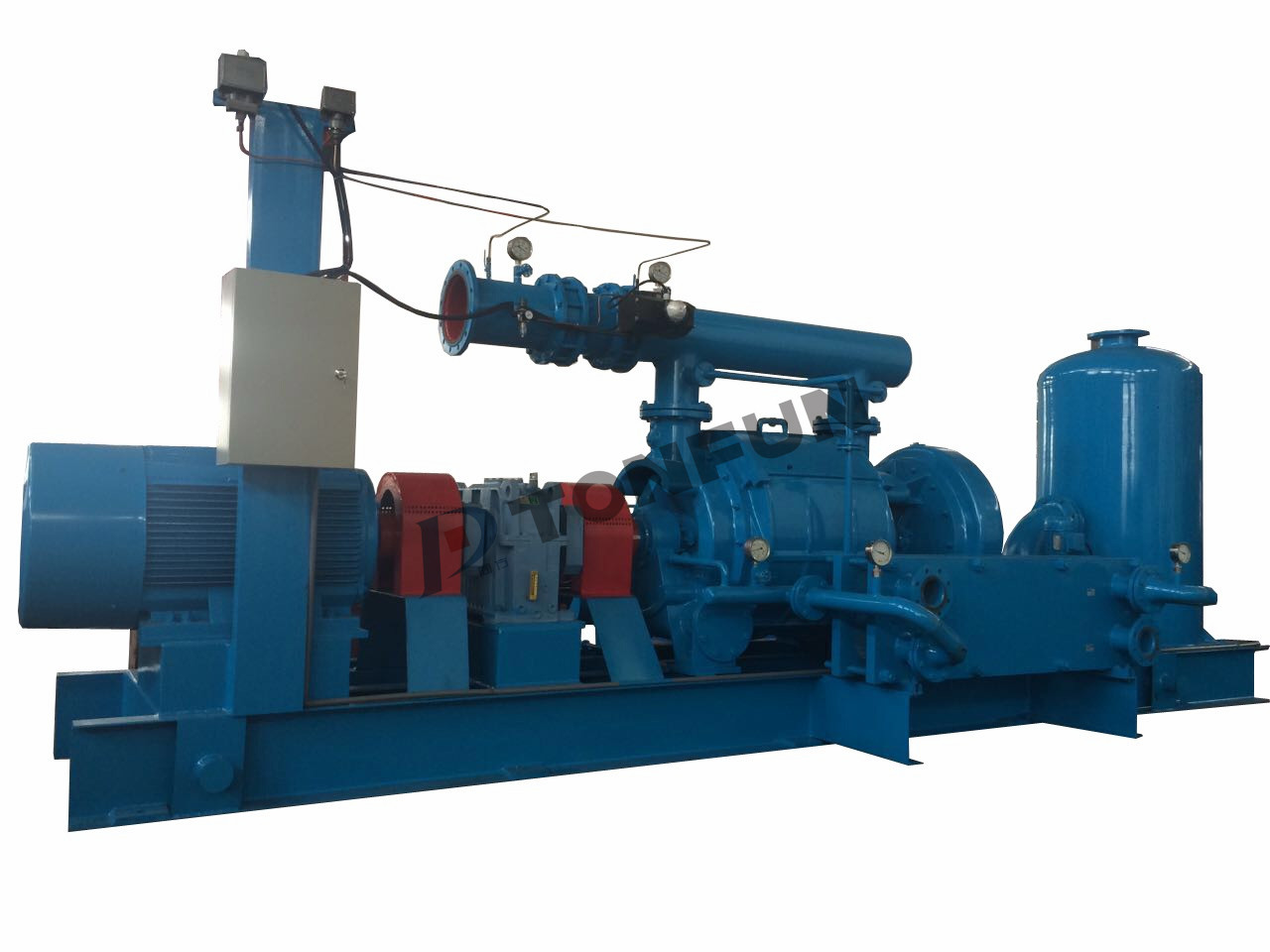

According to the company's Marketing Department, Inner Mongolia datang international toktor power generation co., LTD. Phase five expansion project steam turbine key auxiliary machine ten liquid ring vacuum pump complete sets of units by our company won the bid to provide. The energy saving and emission reduction of thermal power plants are mainly realized by liquid-ring vacuum pump units, which can save more than 30,000 tons of standard coal per year.

The R&D department of the company relies on Huazhong University of science and technology, Wuhan University, Zhongnan electric power design institute and other universities and institutes to carry out industry-university-research cooperation, and has successfully applied for more than 20 national patents. "One kind of corrosion resistant liquid ring vacuum pump" has won the national invention patent, "one million kilowatts grade thermal power nuclear power gas engine condensing vacuum complete set of equipment" and other 21 achievements have won the national utility model patent. TFVP (D) two stage water ring vacuum pump series products are our company draw lessons from foreign similar products technology, and the joint of Huazhong university of science and technology to develop a new product, high efficiency and energy saving with a double function of the special structure design of impeller, the gas through a two stage compression, easier to obtain stable high vacuum independently, in the electric power, chemical, petrochemical and natural gas industry has been widely used.

The company insists on providing a set of schemes, constructing a project, making a group of friends and expanding a market. Pre-sales to "the spirit of the famous", in-depth study of customer needs, customers "tailored", provide a scientific and reasonable project investment budget. Sales based on more than 20 years of industry experience with the "spirit of experts", for customers to solve doubts, provide users with more detailed project working condition requirements of the logical operation data, and industry engineering application standards to do comprehensive solutions. After-sales service is dedicated to the in-depth service of customers with "housekeeping spirit". After-sales service is not only free installation and debugging, but also responsible for technical training for users and technical guidance for engineering systems.